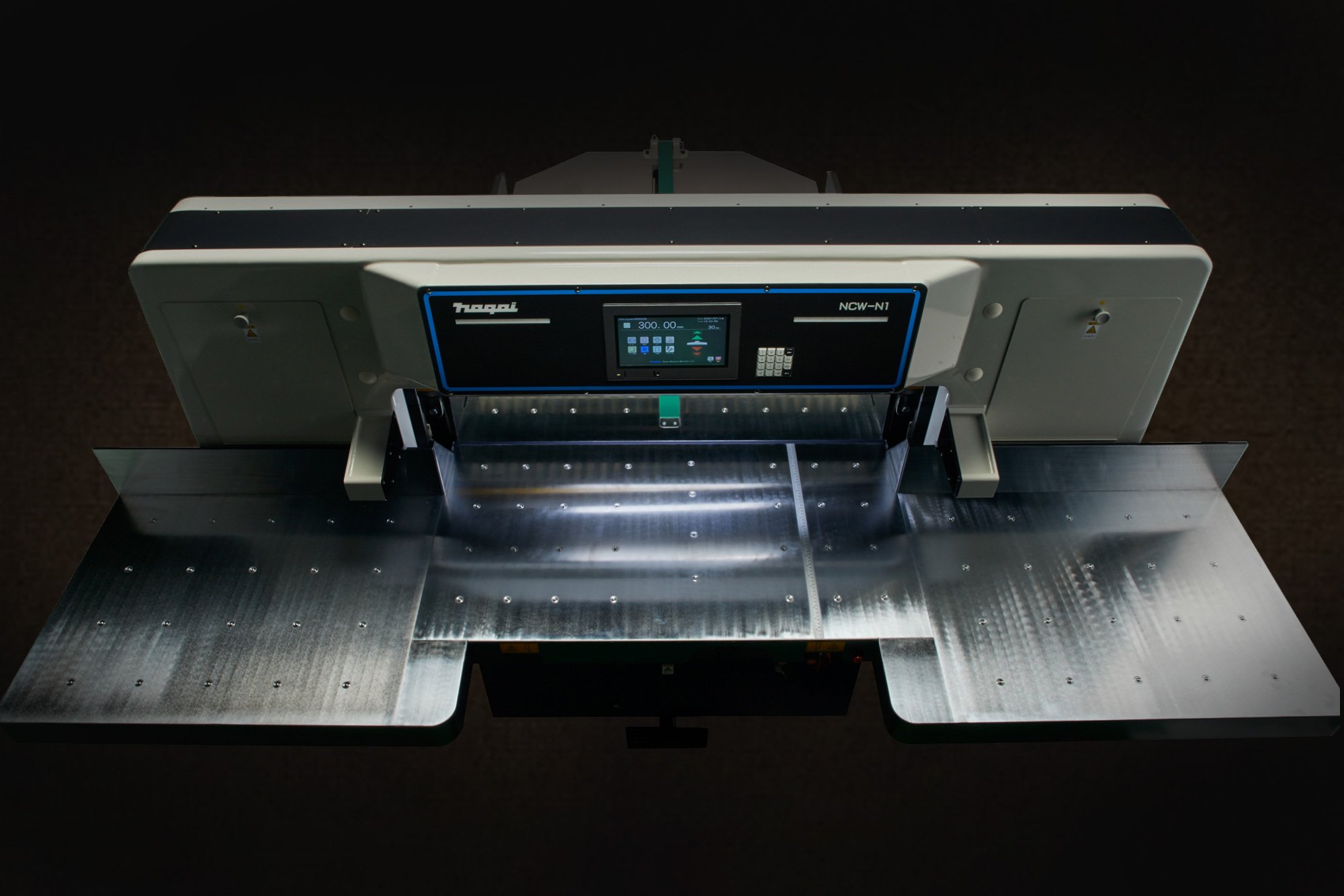

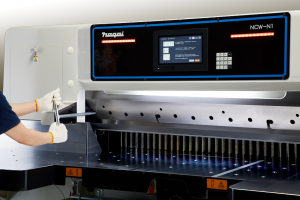

A domestic manufacturer that has been making products, called cutting machines, for over 80 YEARS by accurately examining the materials.

Release cutting machine with a tough body that kept the tradition of HIGH QUALITY and an application that prioritized EASY TO USE.

In order to enable our customers to work more SAFELY, ACCURATELY and SPEEDILY, we have created a next-generation cutting machine by precisely selected each part.

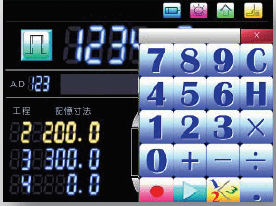

Simple and Innovative Panel Design

The dark gray, which is as close to black as possible, is accented with the blue line, which also represent the company's logo color.

The design of operation panel gives a chic yet Innovative impression.

A 10.5-inch wide touch panel monitor is adopted and possible to select intuitively by iconizing the buttons.

Working Condition can be CHECKED by The Surroundings

Information LED, the newly added to the panel, displays the status of the photocell and the status of the machine, such as when replacing the knife.

The safety of non-operators is also increased by letting others know what kind of work is doing right now, so they can take care of themselves when they are closed to working area.

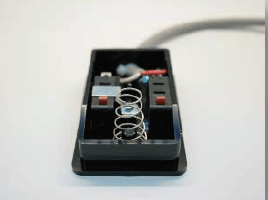

First Priority of Our Keyboard is Flexibility

Keyboard strength is an important part of the cutting machine.Cutting machine work is a long time taking process and if the keyboard is too strong, the operator will have to press the buttons many times in a day, which is tiring. On the other hand, if the keyboard is too light, typing error are likely to occur, and it will be damaged in a short time and difficult to repair.

We use the Cherry MX brown axis, which is the mechanical key that is the top in the keyboard field. Withstands hard use, well-thought-out input position and pushing pressure of 40g that is neither too light nor too heavy. This key has been selected by the world's masters of gaming keyboards.

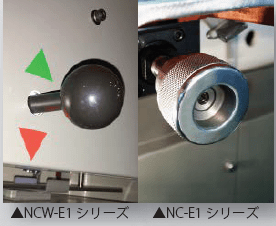

Intuitive Positioning

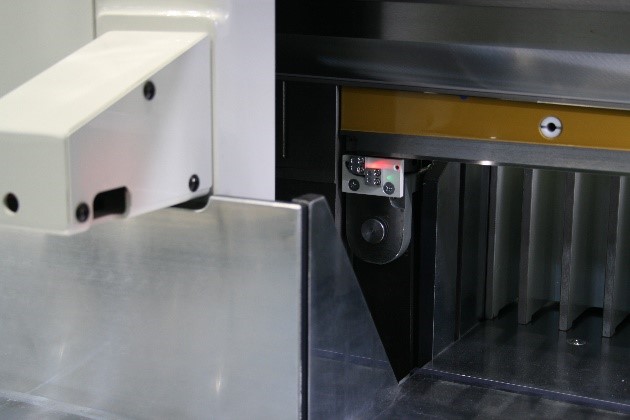

The hand-cranked pulsar, which was developed with a focus on intuitive positioning, changes the moving speed depending on the turning speed.

Even when the distance is a little long and you move with a button, you can also quickly and accurately position by turning the pulsar quickly.

The operator doesn`t need to raise hands for touching the panel so the time to reach the panel can be shortened and work load on the operator is reduced.

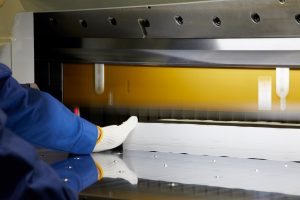

Eliminate the Hassle of Exchanging the Knives

It may be troublesome to adjust the stop position when removing the bolt on the left side. By using the Knife Exchange Mode, it stops at a certain position.

Protect Your Fingers from Accidents

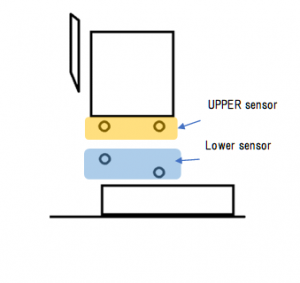

A standard equipment called Clamp Sensor which detects fingers and foreign objects in advance and raises the clamp automatically to protect your fingers pressed by the clamp.The four sensors reduce the occurrence of accidents.

Move slowly at the time of seeing

If you block the photocell, the clamping operation will be slow. Until now, the speed was adjusted by adjusting the step, but by limiting the speed, the risk of accidents can be reduced. In addition, it is even safer when combined with Clamp Sensor.

The space has been set up with easy-to-understand colors and pictograms for intuitive operation. Adopting a large icon and a resistive touch panel that can be pressed even while using work gloves, which are indispensable for work, the design is designed to reduce mistakes in pressing.

As a black background to reduce blue light, it reduces the burden on the operator.

All the functions that have functions but are not used and that are difficult to input are omitted, and the parts that are "Difficult to Operate" are eliminated. You can shorten the time for operator training by limiting the functions so that you can use it immediately even with a little training.

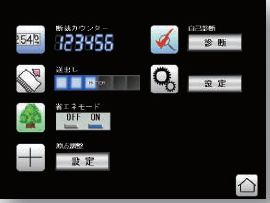

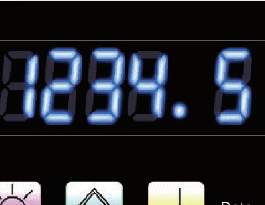

Knife Replacement and Refueling Guideline

We have made it possible to see the situation until the knife is replaced, which is difficult to manage, and the state until grease refueling.

It is now possible to see the status up to the knife replacement in the status bar at the top left of the screen.

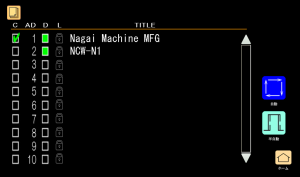

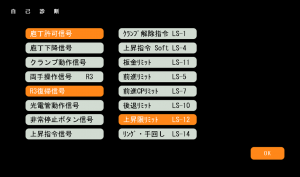

Address List

You can browse the address you are using in a list. By using the title together, can search quickly even in repeat work. You can start the work directly by selecting the address you want to open.

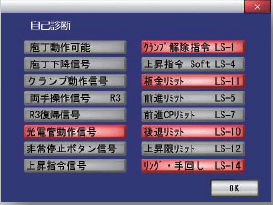

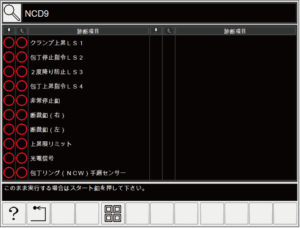

Display Current Status in Self-diagnosis Mode

Displays the current operating status. Therefore, the diagnosis can be executed promptly at the same time as the abnormality occurs, and the abnormality can be figure out with high accuracy. It leads to quick response such as repair and relating process after it.

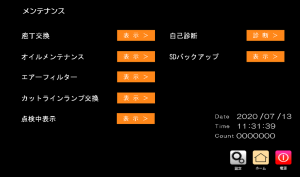

Maintenance Mode

All inspections are summarized in maintenance mode. Knife Replacement, Oil Maintenance, Air Filter, Cut Line, Self-diagnosis, Backup, etc.. can be selected from this mode, which was first adopted in N1 Series.

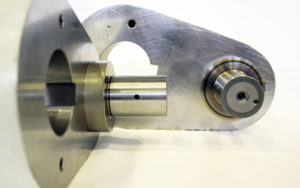

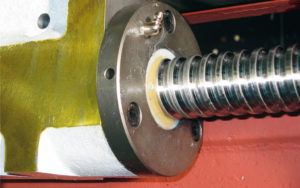

●The NCW-E1 series adopts the middle rod method that allows you to see the adjustment amount as it is.

●The NCW-E1 series adopts the middle rod method that allows you to see the adjustment amount as it is.

-300x225.jpg)

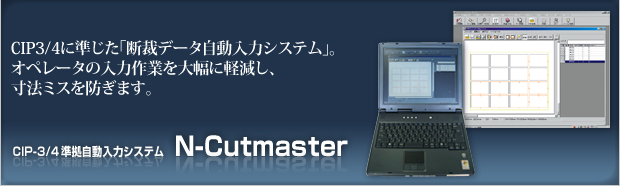

Dedicated mode for operating cutting dimensions.

Dedicated mode for operating cutting dimensions.

-300x225.jpg)

By improving the color scheme of the screen and optimizing the content to be displayed, the visibility is improved and the unprecedented operation crispness is realized. When the icon is touched,the response is expressed by the change in the icon color and the sound. Because the machine will be used for a long time, we respected the open feeling and clear response.

By improving the color scheme of the screen and optimizing the content to be displayed, the visibility is improved and the unprecedented operation crispness is realized. When the icon is touched,the response is expressed by the change in the icon color and the sound. Because the machine will be used for a long time, we respected the open feeling and clear response. A hand-turned pulse handle is struck by the sensation of turning a screw by hand.

A hand-turned pulse handle is struck by the sensation of turning a screw by hand.

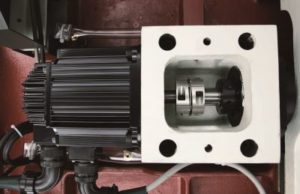

"The Unique Secret of the Silky Touch"

"The Unique Secret of the Silky Touch"

950 mm in length, 70 mm in width, 2 mm in height, Here`s the handy scale tray . Since there is a prominent on the panel, you don`t need to worry the scale drop off during cutting operation. It is easy to take out anytime you want to use.

950 mm in length, 70 mm in width, 2 mm in height, Here`s the handy scale tray . Since there is a prominent on the panel, you don`t need to worry the scale drop off during cutting operation. It is easy to take out anytime you want to use. Attachment of two USB 2.0 compatible communication ports, which can manage system updates and data. Since the communication terminal can be charged, schedule management can be performed near the cutting machine, further accelerating the speed of business up to now. In addition, since you can communicate without worrying about the battery level, you can speedily navigate using a videophone. In addition to this, you can also realize the development of technology transfer using video. It is also possible to leave the intelligence that can not be conveyed only by letters to future generations...

Attachment of two USB 2.0 compatible communication ports, which can manage system updates and data. Since the communication terminal can be charged, schedule management can be performed near the cutting machine, further accelerating the speed of business up to now. In addition, since you can communicate without worrying about the battery level, you can speedily navigate using a videophone. In addition to this, you can also realize the development of technology transfer using video. It is also possible to leave the intelligence that can not be conveyed only by letters to future generations...