Safety Support Device : CLAMP SENSOR

Prevention of finger injury during pedal clamp operation

- During cutting operation, the cutting position of the work is adjusted by the operator by pedaling the foot clamp.At that time, the operator`hand is put under the clamp incautiously and can have an injury unfortunately.

- Until now, safety measures have been taken to prevent accidents, such as attaching a cover to the pedal or using a safety auxiliary device such as a soft clamp to reduce the pedal pressure of the clamp.

- By installing "Soft Clamp Function", even if the finger is put by clamp accidentally, the pedal clamp pressure is restricted to 20kg so the finger did not get injured as expected.

- Nevertheless ...the operator may feel insecure.... "I was surprised when I operated the clamp even though I had my hands in it." "I got injured by pinching my finger." ・ ・ ・

-

What can we do for??

-

Isn't the accident recurring and burdening the cutting operator without taking measures to prevent the accident in a more complete state?

-

For this reason, we will introduce you the "Clamp Sensor" this time.

-

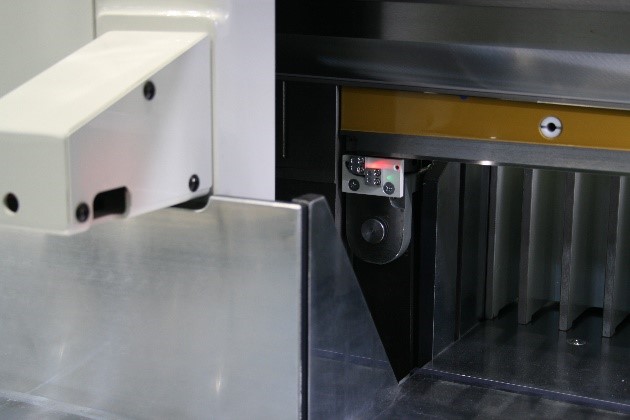

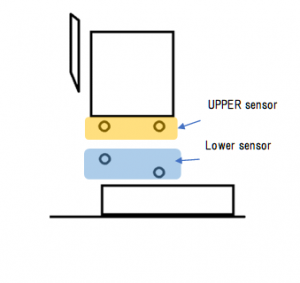

The Sensors beam at the bottom of clamp detects fingers ( or something) , then clamp stop and move up even if pedal has been footed.

-

Don`t you think the operator be more relief than before.