Manual Mode

-300x225.jpg) Dedicated mode for storing cutting dimensions. It is possible to memorize at a fixed size and the number of times, and the tightening pressure for each process can be set even when a product size decreases with each cutting so that the quality of the finish product can be increased.In addition, it is possible to reduce mistakes during operation because instructions can be entered on the screen by entering comments.

Dedicated mode for storing cutting dimensions. It is possible to memorize at a fixed size and the number of times, and the tightening pressure for each process can be set even when a product size decreases with each cutting so that the quality of the finish product can be increased.In addition, it is possible to reduce mistakes during operation because instructions can be entered on the screen by entering comments.

Auto Mode

Dedicated mode for operating cutting dimensions. Since the screens are switched greatly, it is easy to understand that it is in automatic mode. Also,even in the automatic mode, the pulse handle can be enabled for fine adjustment of the dimensions so it is possible to correct the dimensions without switching the screen.

Dedicated mode for operating cutting dimensions. Since the screens are switched greatly, it is easy to understand that it is in automatic mode. Also,even in the automatic mode, the pulse handle can be enabled for fine adjustment of the dimensions so it is possible to correct the dimensions without switching the screen.Mode for Changing Background Colour

Address Setting Mode

-300x225.jpg) In this mode, the stored contents can display in a list and search for available addresses. The name and data can also register to the memorized address. In addition, data can be locked (read-only), so the important data can securely be protected. If you want to use the same data, the address can be copied with the copy function.

In this mode, the stored contents can display in a list and search for available addresses. The name and data can also register to the memorized address. In addition, data can be locked (read-only), so the important data can securely be protected. If you want to use the same data, the address can be copied with the copy function.

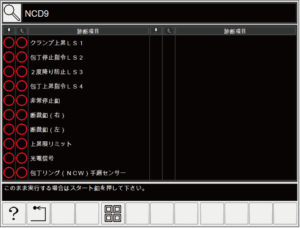

Self-diagnosis Mode

You can display the current state as well as the state when the diagnosis was executed. For this reason, diagnosis can be executed promptly at the same time as the occurrence of an abnormality, and it is possible to grasp the abnormality with high accuracy. Therefore, it leads to quick response such as repair.

You can display the current state as well as the state when the diagnosis was executed. For this reason, diagnosis can be executed promptly at the same time as the occurrence of an abnormality, and it is possible to grasp the abnormality with high accuracy. Therefore, it leads to quick response such as repair.

Sequential Display Switching

Can change the language and display unit settings from the reset screen. You can switch in sequence with one touch of an icon without having to go through the tedious process.In addition, you can add up to 5 languages in addition to the presets.

Can change the language and display unit settings from the reset screen. You can switch in sequence with one touch of an icon without having to go through the tedious process.In addition, you can add up to 5 languages in addition to the presets.

(Japanese, English, Chinese (traditional), Korean, Thai)

High Contrast Main Screen

By improving the color scheme of the screen and optimizing the content to be displayed, the visibility is improved and the unprecedented operation crispness is realized. When the icon is touched,the response is expressed by the change in the icon color and the sound. Because the machine will be used for a long time, we respected the open feeling and clear response.

By improving the color scheme of the screen and optimizing the content to be displayed, the visibility is improved and the unprecedented operation crispness is realized. When the icon is touched,the response is expressed by the change in the icon color and the sound. Because the machine will be used for a long time, we respected the open feeling and clear response.

Fine Adjustment Fastest Legend “PULSE HANDLE”

A hand-turned pulse handle is struck by the sensation of turning a screw by hand. The back gauge operates at high speed when turned quickly, and 0.01 mm when turned slowly. An item that is indispensable for fine adjustment of dragonflies that you can't let go of once you use it.

A hand-turned pulse handle is struck by the sensation of turning a screw by hand. The back gauge operates at high speed when turned quickly, and 0.01 mm when turned slowly. An item that is indispensable for fine adjustment of dragonflies that you can't let go of once you use it.Installation of 12.1-inch Touch Panel

Screen size, power consumption, visibility and detection accuracy are optimistically balanced.The hardware uses a proven matrix resistance film method. In addition, the pressure on the screen is detected as a parameter,the touch input can be performed with gloves. Screws are used as the mechanical fastening method for the stability of operation.

Screen size, power consumption, visibility and detection accuracy are optimistically balanced.The hardware uses a proven matrix resistance film method. In addition, the pressure on the screen is detected as a parameter,the touch input can be performed with gloves. Screws are used as the mechanical fastening method for the stability of operation.

N-Specification Switch

Twin points are used for the electrical contacts to build a double fail-safe. The switch spring has a rate set specifically for cutting and it`s body is used the polycarbonate material to improve durability from every aspect.

Twin points are used for the electrical contacts to build a double fail-safe. The switch spring has a rate set specifically for cutting and it`s body is used the polycarbonate material to improve durability from every aspect.

“Key Touch” for Heavy Users

"The Unique Secret of the Silky Touch"

"The Unique Secret of the Silky Touch"Limit Created by Human Hands

Power Up by 20%

The flywheel, the source of the power of the cutting machine, has been enlarged. The diameter is 340 mm, which is 15 mm larger than before. This slight change has increased the moment of inertia, which is a factor that directly affects sharpness, by 20%.In order to utilize powered up source,the clutch has also more efficient than before.

The flywheel, the source of the power of the cutting machine, has been enlarged. The diameter is 340 mm, which is 15 mm larger than before. This slight change has increased the moment of inertia, which is a factor that directly affects sharpness, by 20%.In order to utilize powered up source,the clutch has also more efficient than before.

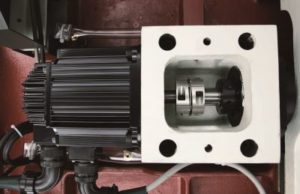

Direct Drive Feeder Motor

Electric motor and drive unit are directly connected by the direct drive which is used for the feeder that moves the back gauge. As a result, compared to the conventional feeder with a reduction gear, the first-order lag element to be controlled can be omitted, and the dynamic characteristics up to the start and stop of the response are extremely good.

Electric motor and drive unit are directly connected by the direct drive which is used for the feeder that moves the back gauge. As a result, compared to the conventional feeder with a reduction gear, the first-order lag element to be controlled can be omitted, and the dynamic characteristics up to the start and stop of the response are extremely good.

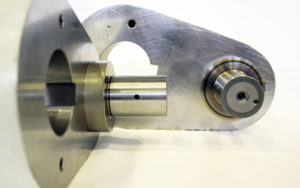

38 mm Reinforced Shaft

The components that convert the rotary motion of the flywheel into the vertical motion of the knife have been strengthened by changing the shaft size from φ32 to φ38. Therefore the moment of inertia of area has been increased by 1.99 times;and thus the rigidity of the system was significantly increased. The performance of high power output source is fully brought out.

The components that convert the rotary motion of the flywheel into the vertical motion of the knife have been strengthened by changing the shaft size from φ32 to φ38. Therefore the moment of inertia of area has been increased by 1.99 times;and thus the rigidity of the system was significantly increased. The performance of high power output source is fully brought out.

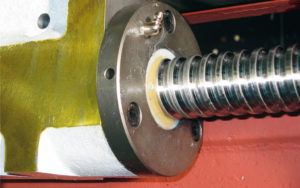

Quiet Grinding Screw

The feed device uses a linear motion mechanism that rotates the screw. A ball type is used for this screw, which has less rotation resistance than general screws. In addition, the screws are polished by grinding and have excellent shape accuracy. Therefore, it keeps the actual moving distance and minimize the display error on the screen.

The feed device uses a linear motion mechanism that rotates the screw. A ball type is used for this screw, which has less rotation resistance than general screws. In addition, the screws are polished by grinding and have excellent shape accuracy. Therefore, it keeps the actual moving distance and minimize the display error on the screen.

Ideal Balance of Machine

The center of gravity is set at a height of 520 mm above the ground. The mass is concentrated in the center as much as possible so the overall mass balance of the cutting machine is improved. As a result, the effect of unnecessary vibration on the knife can be reduced, resulting in stronger cutting and a characteristic cut-off sound.

The center of gravity is set at a height of 520 mm above the ground. The mass is concentrated in the center as much as possible so the overall mass balance of the cutting machine is improved. As a result, the effect of unnecessary vibration on the knife can be reduced, resulting in stronger cutting and a characteristic cut-off sound.

Super High Strength Guide Rail

A unique super high strength guide rail supports the back gauge. Its strength is immovable a 200 kg which is equivalent to the energy level of hundreds of kJ (kilojoules).The guide rail uses an extremely strong material,heat-treated SCM steel,for its reliability.

A unique super high strength guide rail supports the back gauge. Its strength is immovable a 200 kg which is equivalent to the energy level of hundreds of kJ (kilojoules).The guide rail uses an extremely strong material,heat-treated SCM steel,for its reliability.

Pen Tray Attached

160 mm in length, 80 mm in width, 13 mm in height, there is no trouble in placing a pen. When you want to make a marking or to take a memo, you can use it to place a pan as a blind spot.

Scale Tray Attachment

950 mm in length, 70 mm in width, 2 mm in height, Here`s the handy scale tray . Since there is a prominent on the panel, you don`t need to worry the scale drop off during cutting operation. It is easy to take out anytime you want to use.

950 mm in length, 70 mm in width, 2 mm in height, Here`s the handy scale tray . Since there is a prominent on the panel, you don`t need to worry the scale drop off during cutting operation. It is easy to take out anytime you want to use.

USB Port Attachment

Attachment of two USB 2.0 compatible communication ports, which can manage system updates and data. Since the communication terminal can be charged, schedule management can be performed near the cutting machine, further accelerating the speed of business up to now. In addition, since you can communicate without worrying about the battery level, you can speedily navigate using a videophone. In addition to this, you can also realize the development of technology transfer using video. It is also possible to leave the intelligence that can not be conveyed only by letters to future generations...

Attachment of two USB 2.0 compatible communication ports, which can manage system updates and data. Since the communication terminal can be charged, schedule management can be performed near the cutting machine, further accelerating the speed of business up to now. In addition, since you can communicate without worrying about the battery level, you can speedily navigate using a videophone. In addition to this, you can also realize the development of technology transfer using video. It is also possible to leave the intelligence that can not be conveyed only by letters to future generations...

Version Comparison Table

| D1 | D2 | D3 | D5 | D6 | D7 | D9 | |

| 100mm Knief Lifting Unit | ● | ● | |||||

| Brushless Clutch | ● | ||||||

| Turnbuckle | ● | ● | |||||

| Ball Screw/Slide Way | Δ | ● | ● | ● | ● | ||

| Direct Drive | ● | ● | ● | ||||

| Servo Motor | Δ | ● | ● | ● | |||

| Touch Panel | Δ | ● | ● | ||||

| Digital Clamp | ● | ● | |||||

| USB Memory | ● | ||||||

| Two-Handed Type Test | Δ | ● | |||||

| Phototube for Type Verification | Δ | ● | |||||

| Knief Ring Limit | ● | ● | ● | ● | |||

| Knief Slow Motion | Δ | ● | ● | ||||

| Hand Operation Sensor | ● | ● | ● | ||||

| Soft Clamp | (●) | (●) | |||||

| Pen Tray | Δ | ● | ● | ● | ● | ● | |

| Ruler Tray | ● | ● | ● | ● | ● | ||

| Clamp Plate Front Tightening | ● | ● |

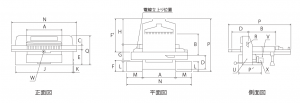

Size of Cutting Machine

| NCW-137HHD9 | NCW-116HHD9 | NCW-102HHD9 | |||

| Cutting Width | mm | A | 1,370 | 1,160 | 1,020 |

| Cutting Length | B | 1,340 | 1,160 | 1,020 | |

| Cutting Thickness | C | 160 | 165 | 155 | |

| Front Table Length | D | 695 | 635 | 635 | |

| Table Height | E | 850 | 850 | 850 | |

| Front Base Length | F | 700 | 690 | 600 | |

| Back Table Length | G | 1,740 | 1,480 | 1,290 | |

| Base Length | H | 790 | 790 | 790 | |

| Base Rear Length | I | 1,315 | 1,065 | 875 | |

| Frame Width | J | 2,520 | 2,360 | 2,220 | |

| Shaft Protrusion Width | K | 10 | 10 | 10 | |

| Side Table Length | L | 650 | 650 | 560 | |

| Side Table Width | M | 850 | 850 | 750 | |

| Machine Width | N | 3,070 | 2,860 | 2,520 | |

| Machine Length | O | 2,805 | 2,545 | 2,265 | |

| Machine Length(Bottom) | P | 1,050 | 1,050 | 1,050 | |

| Machine Height | Q | 1,565 | 1,560 | 1,560 | |

| Knief Length | R | 1,610 | 1,390 | 1,250 | |

| Maximum Tightening Pressure | kg | S | 4,000 | 4,000 | 4,000 |

| Number of Cuts per minute | 回/min | T | 42 | 42 | 42 |

| Motor for Knife | kw | U | 1.5 | 1.5 | 1.5 |

| Tightening Motor | V | 1.5 | 1.5 | 1.5 | |

| Feeding Motor | W | 0.6 | 0.6 | 0.6 | |

| Air Motor | X | 0.85 | 0.85 | 0.42 | |

| Total Power Capacity | Y | 4.45 | 4.45 | 4.02 | |

| Weight | kg | Z | 4,400 | 4,000 | 3,500 |