Reduce running costs by inspection! ??

By performing preliminary maintenance such as pre-start inspections and regular self-inspections, abnormal parts can be found, and repairs, adjustments, refueling, etc. can be performed before they become major problems, which reduces the cost and downtime required for repairs.

For example, if you continue to use the bearing without noticing that there is a problem, it can affect to its connecting parts and you have to replace the shaft and seals as the result of the bearing problem. What if you know the problem from it`s beginning, you only need to replace the bearing which can save your time and repair cost.

By finding problem areas early through pre-start inspections and regular self-inspections, and after that improving them while the problems are small. Unexpected downtime and high repair costs can be suppressed, and the machine can be used safely.

It is legally obligatory to inspect! ??

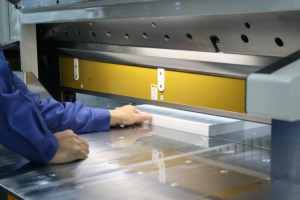

Did you know that cutting machines are required to carry out a self-inspection at the start of work and a regular self-inspection every year?

・ According to Article 135 of the Occupational Safety and Health Regulations

The cutting machine is supposed to carry out an annual self-inspection once a year and keep the record for 3 years.

・ According to Article 136 of the Occupational Safety and Health Regulations

It is stipulated that an inspection be carried out before the start of work on that day.

By conducting regular pre-work inspections and regular self-inspections, you can prevent occupational accidents and keep the machine in good condition. By improving the condition of the machine, the number of repairs can be reduced, the downtime can be shortened, and the cutting accuracy can be improved, leading to the reduction of defects.

What do you do in the pre-work inspection?

In the pre-work inspection, there are a set of inspection items for normal use of the cutting machine, such as checking for abnormalities on the appearance of the machine, clutch operating status, one-process-one-stop status, knife slide mechanism, refueling, etc.

Check the appearance and operating conditions, and make sure that you can work safely before starting work.

Our cutting machine comes with a pre-work checklist in the instruction manual.

Please take advantage of it. If you have any questions, please feel free to contact us.

What do you do in the regular self-inspection?

In the regular self-inspection of the cutting machine, it is necessary to check based on a detailed inspection table rather than the pre-work inspection, and the record is to be retained for 3 years.

Therefore, it is necessary to create an inspection table that not only checks the condition of each safety device, but also checks the looseness of bolts, the damage status of parts, the wear status of parts, and the deterioration status of electrical wiring.

Since it is a regular self-inspection, it is possible to do it voluntarily, but since it is required to know the "Normal state", I think that it will be necessary for someone who has some experience and knowledge to do the work.

Since it is a machine that processes using blades and hydraulic system, safety is prioritized, so it is recommended that an inspector with some experience and expertise inspect it. It's too late after the accident.

I got a checklist, what should I do?

It is obligatory to keep the inspection table (regular voluntary inspection table for cutting machines) for 3 years.

You may be asked to show this to the Labor Standards Inspection Office, so please keep it in a safe place when you inspect it.

Can I request a regular self-inspection because I can't do it by myself?

We provide a regular self-inspection service. Based on the inspection table, we perform a simple cleaning of the inside, check the detailed inspection items of each part, and also perform adjustment work.

In addition, we will report any parts that need adjustment or repair, and if it is simple, we will repair it on the spot.

A service person who is familiar with the cutting machine will respond, so we will perform inspections and adjustments unique to the manufacturer.

It is a cutting machine that I usually use, but if you have any questions about how to use or maintain the cutting machine, please feel free to ask a question.

I have explained about pre-start inspections, regular self-inspections so far. How do you think?

The other day, we received a story from a customer saying, "By conducting regular self-inspections, the cost of annual maintenance has been significantly reduced."

We hope that you will carry out preliminary maintenance and use the machine safely while reducing costs.

If you have any questions, please feel free to ask us by using the inquiry form or by phone.