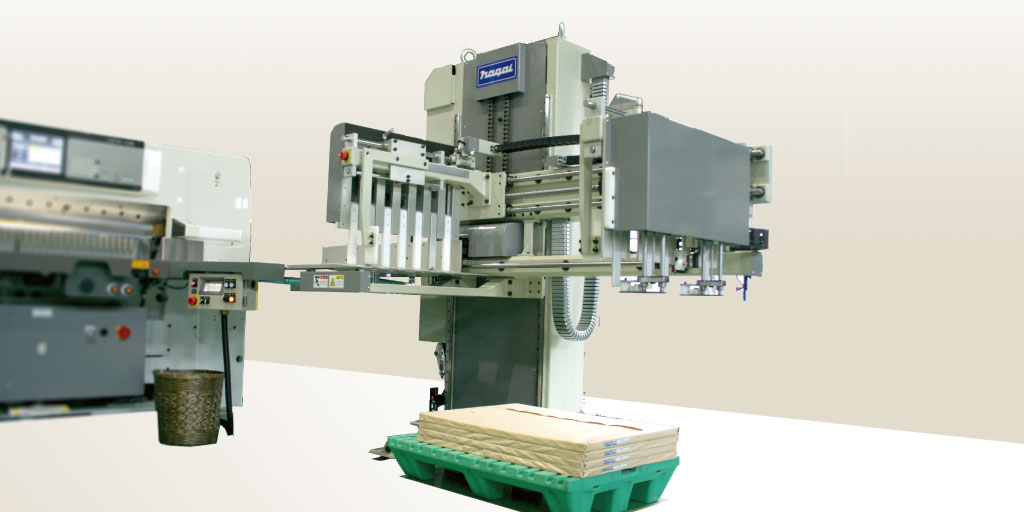

- The compact paper stacker is equipped with horizontal alignment and automatic dimension adjustment functions as standard equipment.

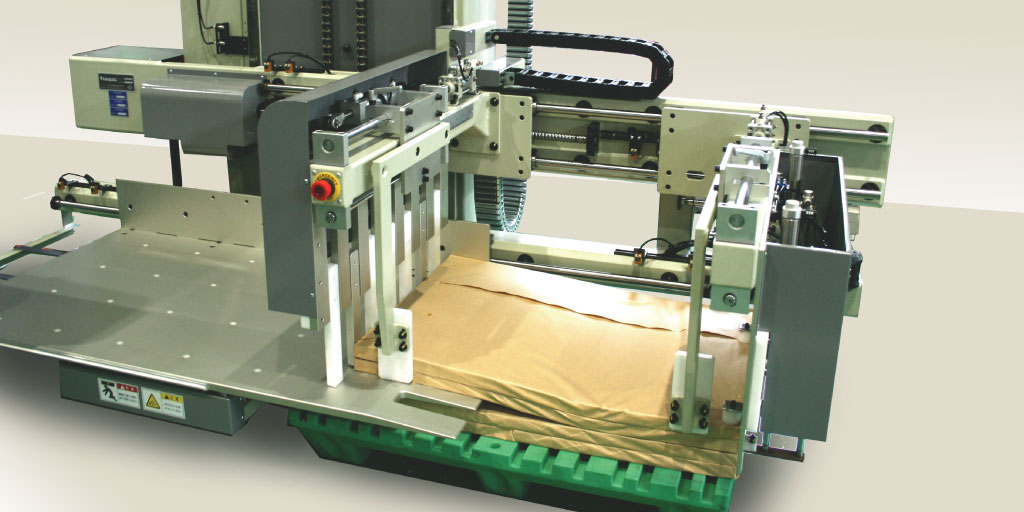

- ●Isn’t the work of transferring the cut product to the pallet a heavy burden on the waist?

- ●Also, isn’t the corner of the finished product broken because it is not stacked all together, or is there any work such as reloading in a later process?

- ●Work efficiency can be increased by about 1.5 to 2 times from the time of manual loading, and products can be stacked neatly.

- ●The B all compact stacker is a minimum size that saves space compared to the conventional paper ejection stacker. Even if it is small, it can handle all B sizes.

- ●When stacking paper, the longitudinal direction does not need to be adjusted due to automatic positioning.

- ●In addition, since it is equipped with a horizontal twist function as standard equipment, it can be easily misaligned in the horizontal direction, making post-processes easier.

- ● Since the power is operated by electricity and air, troublesome oil maintenance is not required, and a tape switch type emergency stop switch around the table allows safe use.

Sizes of Compact Paper Stacker

| A | Overall Length | 3,000mm | I | Maximum Frontage | 1,258mm | |

| B | Dimensions behind the center of the main body | 1,270mm | J | 530mm | ||

| C | Dimensions in front of the center of the main body | 1,732mm | Maximum Paper Size | 1,100×800mm | ||

| D | Overall Breadth | 1,435mm | Minimum Paper Size | 550mm | ||

| E | Air-Table Breadth | 800mm | Maximum Height for 1Rim | 165mm | ||

| F | Air-Table Length | 1,320mm | Maximum Height(Pallet Included) | 1400mm | ||

| G | Overall Height | 2,055mm | Required Power | 1.8kW | ||

| H | Maximum Height(When table rises) | 2,150mm | Total Weight | 2,000kg |